Product Oil Storage Tank Cleaning System

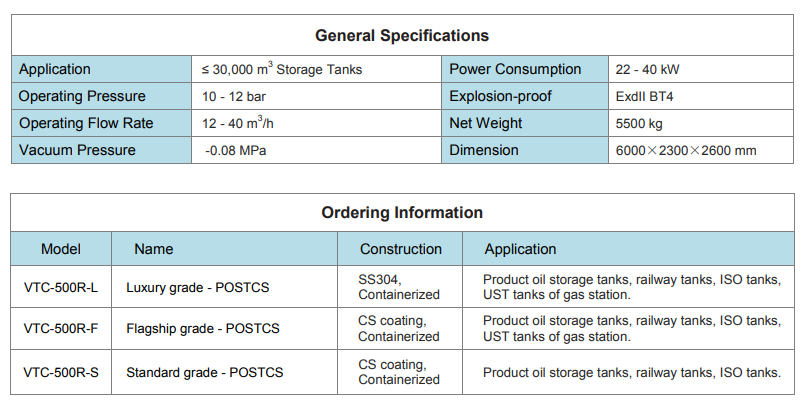

VTC-500R is a mechanical automatic cleaning system equipment for product oil tanks with a volume of less than 30,000 cubic meters, which was developed after years of practical verification. It has won the first batch of industrial cleaning industry brand product certification from the Industrial Cleaning Association of China (ICAC).

Category:

Oil Tank Cleaning Systems

Key Word:

product oil tank cleaning

Product Accessories:

Description

VTC-500R Product Oil Storage Tank Cleaning System (POSTCS)

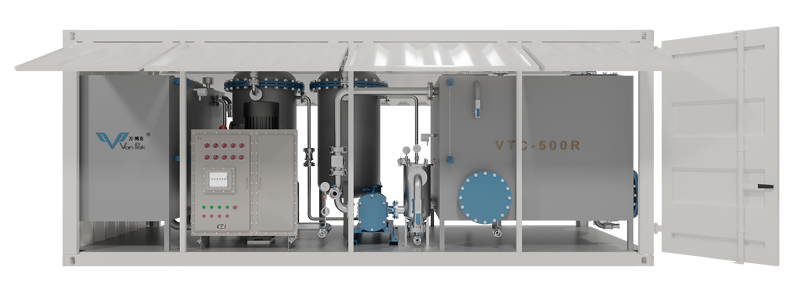

VTC-500R is a mechanical automatic cleaning system equipment specially designed for large and medium-sized product oil tanks below 30,000m3, which is developed by Vanpek Company through years of practice and verification by adopting multiple patented technologies such as low-pressure water jet three-dimensional cleaning and oily water separation treatment. The system equipment function modules include: cleaning module, sewage pumping module, oily water three-phase separation module, precision filtering module, intelligent electronic control module, etc.

VTC-500R is a set of intelligent cleaning system for product oil storage tank that realizes mechanical automation and recycling of cleaning water, and has won the first batch of industrial cleaning industry brand product certificates issued by Industrial Cleaning Association of China (ICAC).

The VTC-500R cleaning system can clean the product oil storage tanks (including dome roof tanks, floating roof tanks and inner floating roof tanks) below 30,000m3. The three-dimensional jet cleaning nozzle driven by hydraulic water flow is adopted. According to the limitation of the opening size and position of the tank, 360 ° omnidirectional cleaning nozzle is adopted for the cleaning of the dome roof tank, and the nozzle is inserted into the tank from the manhole at the top of the tank (the middle position is preferred); For the floating roof tank, 105 ° directional cleaning nozzle is used, and the nozzle is installed in the side manhole near the bottom of the tank wall. During cleaning, no personnel are required to enter the tank for operation. The hydraulic water directly drives the nozzle to form a 360 ° spherical surface or a 105 ° sector covering the cleaning track in the tank, so that the inner bottom plate of the tank can be cleaned thoroughly.

The VTC-500R cleaning system will treat the oily sewage generated by cleaning with a special three-phase separation and precision filtering device for mud, oil and water, and the effluent can be recycled again for cleaning. It can realize continuous and uninterrupted cleaning service, and is suitable for the business needs of mechanical automatic cleaning of large and medium-sized product oil storage tanks.

Relevant case:

Related products

Inquiry

*Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible